Electromechanical universal testing machines deliver precise, stable loading through a high-performance motor-driven crosshead. Unlike hydraulic systems, they offer clean, quiet, and maintenance-free operation, eliminating the risk of oil leaks, reducing downtime, and ensuring a consistently controlled testing environment.

-

- Electromechanical Universal Testing Machine, Single Column Table-Top

-

Test load 10N-5kNType of test

- Tensile Test

- Compression Test

- Bend & Flexural Test

- Shear Test

- Peel Test

- Tear Test

Standards- ISO

- ASTM

- GB/T

- JJG

-

- Electromechanical Universal Testing Machine, Dual Column Table-Top

-

Test load 100N-10kNType of test

- Tensile Test

- Compression Test

- Bend & Flexural Test

- Shear Test

- Peel Test

Standards- ISO

- ASTM

- GB/T

- JJG

-

- Electromechanical Universal Testing Machine, Dual Column Table-Top

-

Test load 5kN-50kNType of test

- Tensile Test

- Compression Test

- Bend & Flexural Test

- Shear Test

Standards- ISO

- ASTM

- GB/T

- JJG

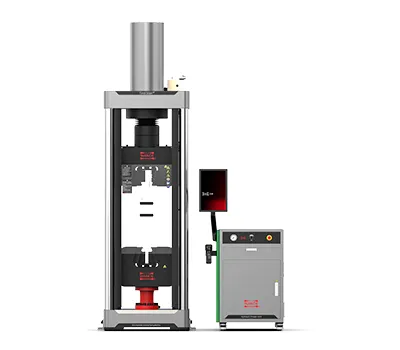

Servo-hydraulic universal testing machines apply force through a hydraulically driven actuator and are available in both single-test-space (lower space) and dual-test-space configurations. Depending on the application, the system can be equipped with hydraulic wedge grips or hydraulic side-action grips to ensure secure, high-stability specimen clamping.

-

- Servo-Hydraulic Universal Testing Machine, Dual Space, Wedge Action Grip

-

Test load 300kN~3000kNType of test

- Tensile Test

- Compression Test

- Bend & Flexural Test

- Shear Test

Standards- ISO

- BS

- ASTM

-

- Servo-Hydraulic Universal Testing Machine, Single Space, Wedge Action Grip

-

Test load 600kN~2000kNType of test

- Tensile Test

- Compression Test

Standards- ISO

- BS

- ASTM

-

- Servo-Hydraulic Universal Testing Machine, Single Space, Side Action Grip

-

Test load 500kN-2000kNType of test

- Tensile Test

- Compression Test

Standards- ISO

- BS

- ASTM

Pendulum impact testing machines measure the energy absorbed by a material under impact loading, providing a direct evaluation of its impact strength and toughness. Understanding a material’s energy-absorption characteristics is essential for predicting how much plastic or permanent deformation it can tolerate before failure.

-

- Pendulum Impact Testing Machine for Plastics, Charpy/Izod Impact Test

-

Max. energy 50JType of test

- Charpy Impact Test

- Izod Impact Test

- Tensile Impact Test

Standards- ISO

- ASTM

-

- Pendulum Impact Testing Machine for Metals, Charpy Impact Test (150J-450J)

-

Max. energy 450JType of test

- Charpy Impact Test

Standards- ISO

- ASTM

- EN

- GB/T

- GOST

-

- Pendulum Impact Testing Machine for Metals, Charpy Impact Test (300J-750J)

-

Max. energy 750JType of test

- Charpy Impact Test

Standards- ISO

- ASTM

- EN

- GB/T

- GOST

A drop weight impact tester evaluates the impact strength and fracture behavior of materials by releasing a defined weight from a specific height to deliver a controlled impact energy and velocity onto the material. It is widely used to determine the energy required to cause cracking, penetration, or complete failure of plastics, composites, and metallic materials.

-

- Drop Weight Impact Testing Machine for Plastics

-

Max. energy 300JType of test

- Drop Weight Impact Test

Standards- ISO

- BS EN

- ASTM

- GB/T

-

- Drop Weight Impact Testing Machine for Composites

-

Max. energy 300JType of test

- Drop Weight Impact Test

Standards- ASTM

- GB/T

-

- Drop Weight Impact Testing Machine for Metals and Non-Metals, High Speed

-

Max. energy 1800JType of test

- Drop Weight Impact Test

Standards- ASTM

- ISO

- EN

- DIN

Dynamic fatigue testing machines are designed to perform repeated cyclic loading on materials and components. Unlike universal testing machines which apply quasi-static loads to determine yield strength, tensile strength, and ultimate failure, fatigue testing systems typically load materials within the elastic range until failure occurs due to accumulated fatigue damage.

-

- Electrodynamic Fatigue Testing Machine

-

Test load 20kNType of test

- High-Cycle Fatigue Test

- Low-Cycle Fatigue Test

- Fracture Mechanics Test

Standards- ASTM

- GB/T

- ISO

-

- Servo-Hydraulic Fatigue Testing Machine, Table-Top

-

Test load 25kNType of test

- High-Cycle Fatigue Test

- Low-Cycle Fatigue Test

- Fracture Mechanics Test

Standards- ASTM

- GB/T

- ISO

-

- Servo-Hydraulic Fatigue Testing Machine, Floor-Standing

-

Test load 2000kNType of test

- High-Cycle Fatigue Test

- Low-Cycle Fatigue Test

- Fracture Mechanics Test

Standards- ASTM

- GB/T

- ISO

Used to evaluate long-term failure time under constant internal pressure and temperature, or the instantaneous burst pressure, of thermoplastic and composite pipes such as PP-R, PP-B, PP-A, PE, PE-X, PVC, PVC-U, PVC-C, and aluminum-plastic multilayer pipes.

-

- Melt Flow Indexer (Manual)

-

Methods Method A, Method BType of test

- Melt Flow Index Test

Standards- ISO

- ASTM

- JJG

- GB/T

- JB/T

-

- Melt Flow Indexer (Automatic)

-

Methods MFR, MVRType of test

- Melt Flow Index Test

Standards- ISO

- ASTM

- JJG

- GB/T

-

- HDT/Vicat Testing Machine

-

Methods Method A, Method B, Method CType of test

- HDT/Vicat Test

Standards- ISO

- ASTM

- GB/T

High-temperature creep and stress rupture testing machines are designed to measure the creep behavior and long-term rupture strength of metallic materials under constant tensile load and elevated temperatures. Creep testing machines are available in two configurations: Lever (mechanical) systems and electronic systems

-

- Electromechanical Creep & Stress Rupture Testing Machine

-

Test load 100kNType of test

- High-Temperature Stress-Rupture Test

- High-Temperature Creep Test

- Stress-Relaxation Test

- Cyclic Loading Test

Standards- ASTM

- ISO

- GB/T

-

- Lever Arm Creep & Stress Rupture Testing Machine

-

Test load 100kNType of test

- High-Temperature Stress-Rupture Test

- High-Temperature Creep Test

Standards- ASTM

- ISO

- GB/T

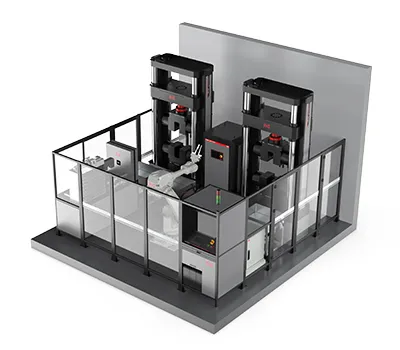

WANCE robotic automated testing solutions are engineered to increase laboratory throughput, enhance test repeatability, and elevate operator safety. By automating repetitive operations including specimen handling, dimensional measurement, alignment, loading, and test execution, laboratories can reallocate skilled personnel to higher-value analytical and engineering work.

-

- Robotic Automated Bar Tensile Testing System

-

Test load 2000kNType of test

- Bar Tensile Test

Standards- ISO

- BS

- ASTM

-

- Robotic Automated Sheet Tensile Testing System

-

Test load 2000kNType of test

- Sheet Tensile Test

Standards- ISO

- BS

- ASTM

-

- Robotic Automated Concrete Compression Testing System

-

Test load 3000kNType of test

- Concrete Compression Test

Standards- GB/T

- CS1

- ASTM

- AASHTO

A compression testing machine refers to a testing frame dedicated solely to compressive testing. It is primarily used for determining the compressive strength, elastic modulus, and Poisson’s ratio of construction materials such as concrete, cement, masonry blocks, and rock specimens.

-

- Compression Testing Machine, Servo Valve Control

-

Test load 3000kNType of test

- Compression Test

Standards- CS1

- ASTM

- AASHTO

- GB/T

-

- Compression Testing Machine, Servo Motor Control

-

Test load 3000kNType of test

- Compression Test

Standards- CS1

- ASTM

- AASHTO

- GB/T

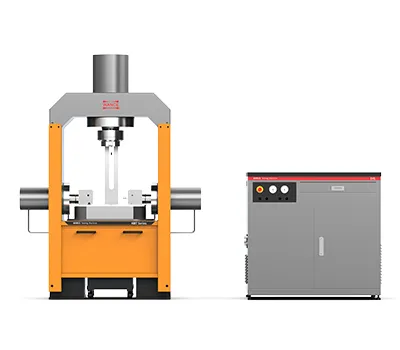

Supports thin metal sheets (<4 mm), especially automotive-grade sheet materials requiring precise 180° bending performance evaluation. Fully compliant with the VDA 238-100 flexural testing standard defined by the German Automotive Industry Association.

-

- Rebar Bend & Re-bend Testing Machine

-

Test load 300kNType of test

- 180°Bend Test

- 90° Bend Test

- Re-bend Test

Standards- ASTM

- ISO

- GB/T

- BS

- DIN

-

- Metal Plate Bend Testing Machine

-

Test load 3000kNType of test

- Metal Plate Multi-Angle Bend Test

Standards- GB/T

- ISO

- GOST

- ASTM

-

- Sheet Metal Bend Testing Machine

-

Test load 100kNType of test

- Three-Point Bend Test

- Flattening Test

Standards- GB/T

- ISO

- VDA

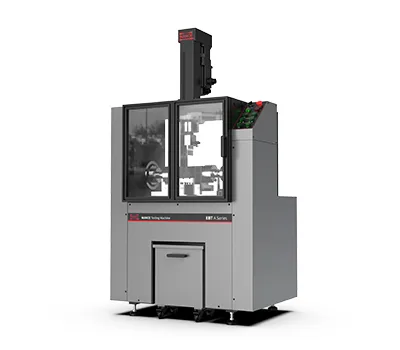

Torsion testing machines are typically categorized into material torsion testers and wire torsion testers, supporting a wide range of specimen from metallic bars and tubes to wires and composite materials. These instruments are widely used in metallurgy, aerospace, quality inspection, and research laboratories for determining torsional performance, structural reliability, and material deformation behavior under rotational loading.

-

- Table-Top Torsion Testing Machine

-

Type of test

- Torsion Test

Maximum torque- 5000Nm

-

- Wire Torsion Testing Machine

-

Type of test

- Wire Torsion Test

Maximum torque- 200Nm

We also provide a variety of accessories for all types of mechanical testing equipment.