Request a Quote

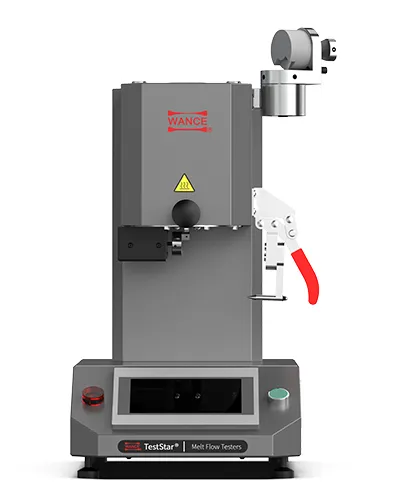

MFI452B

Melt Flow Indexer (Manual)

The series melt flow index testers are precision instruments designed to measure the melt flow rate of thermoplastic materials under specified test conditions. The melt flow rate (MFR) or melt volume rate (MVR) represents the mass or volume of molten polymer extruded through a standardized die within 10 minutes at a defined temperature and load. This parameter is critical for assessing polymer processing behavior, ensuring material consistency, and supporting batch quality control across production environments.

Common Applications: Thermoplastics including:

- General-purpose plastics: PE, PP, PS, ABS, PVC, etc.

- Engineering plastics: PA (Nylon), PC, POM, PBT, PET, and others.

Standards

ISO 1133-1, ISO 1133-2, ASTM D1238, JJG 878, GB/T 3682.1, GB/T 3682.2, JB/T 5456

Specifications

| Model | MFI452B |

| Temperature range | 50-450℃ |

| Temperature variation in 4 hours | ≤±0.5℃ |

| Maximum permitted deviation from the required test temperature: 75mm above the top surface of the standard die | ≤0.25℃ |

| Temperature Resolution | 0.1℃ |

| Measurement range | Method A: 0.1-50 Method B: 0.1-2000 |

| Displacement error | ≤±0.02 mm |

| Displacement resolution | 0.003 mm |

| Displacement measurement range | 25.5 mm |

| Interval of temperature recovering after changing testing samples | ≤3 minute |

| Resolution of timing | 0.01 second |

| Inner diameter of die | ⌀2.095±0.005 mm |

| Inner diameter of cylinder | ⌀9.550±0.007 mm |

| Weights accuracy | ≤±0.5% |

| Standard weights | 325g, 1200g, 2160g, 3800g, 5000g, 10000, 21600 |

| Dimension | 350x435x660 mm |

| Weight | 35 kg |

| Electric supply | 1.5kW (220V±10%, AC, 50Hz) |

Details

We also provide a variety of accessories for all types of mechanical testing equipment.