-

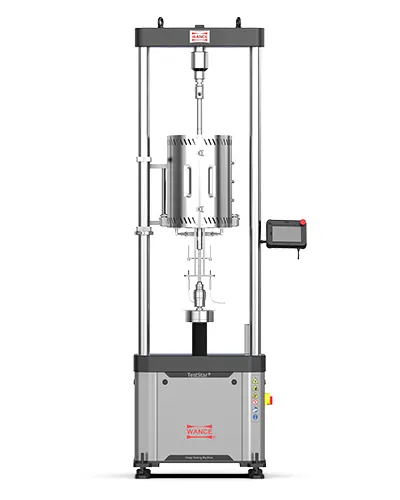

- Electromechanical Creep & Stress Rupture Testing Machine

The electromechanical creep and stress rupture testing machine is designed for long-duration high-temperature testing of metallic materials.

- Type of test: High-Temperature Stress-Rupture Test, High-Temperature Creep Test, Stress-Relaxation Test, Cyclic Loading Test

- Test load: 100kN

- Standards: ASTM, ISO, GB/T

-

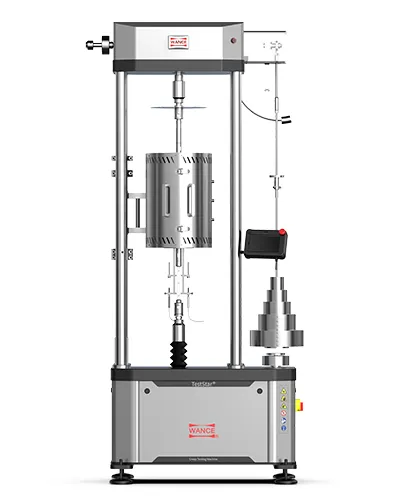

- Lever Arm Creep & Stress Rupture Testing Machine

It is suitable for creep and stress-rupture on specimens made from superalloys, titanium alloys, ferrous and non-ferrous metals in both bar and plate form.

- Type of test: High-Temperature Stress-Rupture Test, High-Temperature Creep Test

- Test load: 100kN

- Standards: ASTM, ISO, GB/T