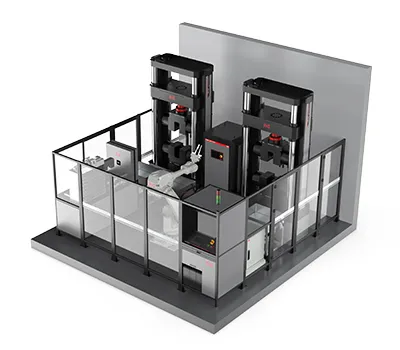

WANCE robotic automated testing solutions are engineered to increase laboratory throughput, enhance test repeatability, and elevate operator safety. By automating repetitive operations including specimen handling, dimensional measurement, alignment, loading, and test execution, laboratories can reallocate skilled personnel to higher-value analytical and engineering work. We offer both fully integrated turnkey robotic platforms and modular automation packages that interface seamlessly with existing testing equipment. Each configuration is customizable to meet project-specific requirements. These robotic solutions deliver wide-ranging manipulation and processing capabilities and can be adapted for tensile, bend, and compression testing across plastics, films, metals, and various structural components.

-

- Robotic Automated Bar Tensile Testing System

For round metallic specimens. Features shoulder grips and an automated diameter-measurement module.

- Type of test: Bar Tensile Test

- Test load: 2000kN

- Standards: ISO, BS, ASTM

-

- Robotic Automated Sheet Tensile Testing System

For tensile testing of flat metal dogbone specimens. Features hydraulic side-action grips and a cross-section measurement module.

- Type of test: Sheet Tensile Test

- Test load: 2000kN

- Standards: ISO, BS, ASTM

-

- Robotic Automated Rebar Tensile Testing System

For rebar tensile testing. Features hydraulic side-action grips and automated gauge-length and diameter measurement modules.

- Type of test: Rebar Tensile Test

- Test load: 2000kN

- Standards: ISO, BS, ASTM

-

- Robotic Automated Concrete Compression Testing System

For concrete compression testing. Features one robotic arm paired with a single compression frame, or as a higher-throughput setup with one robotic arm operating three synchronized compression testing machines.

- Type of test: Concrete Compression Test

- Test load: 3000kN

- Standards: GB/T, CS1, ASTM, AASHTO

-

- Robotic Automated Charpy Impact Testing System

For metallic Charpy impact evaluation.

Features automatic notch-alignment capability and a low-temperature conditioning chamber.- Type of test: Charpy Impact Test

- Max. energy: 750J

- Standards: ISO, EN, ASTM, GB/T, GOST