Robotic Automated Sheet Tensile Testing System

The robotic automated sheet tensile testing platform enables fully unattended tensile testing of metallic sheet specimens. This configuration forming a continuous end-to-end testing workflow, from specimen loading, cross-section measurement, tensile testing, specimen removal, to data upload.

Operators simply place specimens of various shapes and sizes into the storage rack. Until results are transmitted to the host database, every step is executed automatically: robotic pickup, geometric measurement, alignment, gripping, parameter configuration, automatic gauge-length switching, test execution, data evaluation, data upload, and waste-specimen disposal. All specimen types within the rated capacity can be tested without changing grips, fixtures, or making any manual adjustments. The testing platform is designed for high throughput, operator safety, and test repeatability, with integrated automatic fault detection and alarm functions to ensure reliable long-term operation.

ISO 7500-1, ISO 9513, ISO6892, ISO 15630, ISO 15835, BS 4449, ASTM E8, ASTM E 83, ASTM E4, ASTM A370, ASTM A416

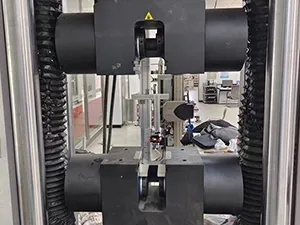

Universal testing machine

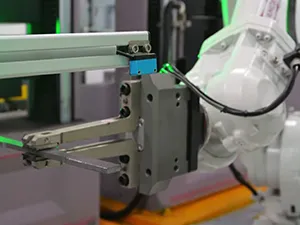

Universal testing machine Robotic arm

Robotic arm Digital controller

Digital controller Load cell

Load cell Automatic extensometer

Automatic extensometer Cross-section measurement unit

Cross-section measurement unit Video extensometer

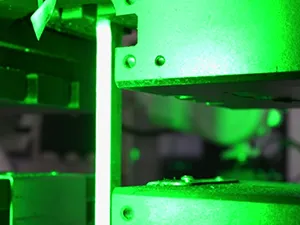

Video extensometer Hydraulic side-action grips

Hydraulic side-action grips Specimen storage rack

Specimen storage rack Video extensometer

Video extensometer

Testing efficiency

FESTO linear robot (Germany):

- Up to 120 specimens per batch

- Throughput up to 24 specimens/hour (thin sheet)

ABB 6-axis robot:

- Up to 60 specimens per batch

- Throughput up to 15 specimens/hour (medium & thick plate)

We also provide a variety of accessories for all types of mechanical testing equipment.