-

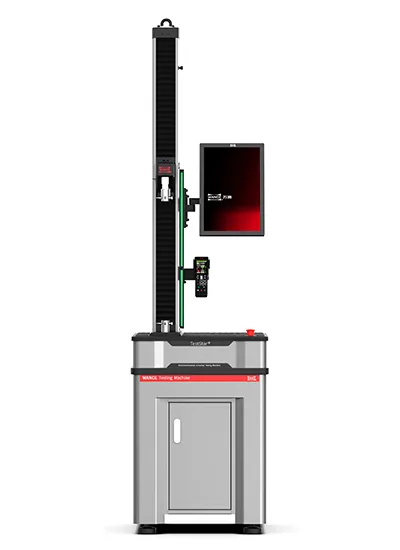

- Electromechanical Universal Testing Machine, Single Column Table-Top (10N-5kN) Designed with single column table-top structure, the electromechanical universal testing machine is engineered for low-force material testing, providing load capacities up to 5kN for tensile, compression, bending, shear, peel, and tear applications.

- Test load: 10N-5kN

- Type of test: Tensile Test, Compression Test, Bending Test, Shear Test, Peel Test, Tear Test

- Standards: ISO, ASTM, GB/T, JJG

-

- Electromechanical Universal Testing Machine, Dual Column Table-Top(100N-10kN) The electromechanical universal testing machine, featuring dual column table-top configuration, is designed for medium-load material testing, offering load capacities up to 10kN for tensile, compression, bending, shear, peel, and other complex mechanical applications.

- Test load: 100N-10kN

- Type of test: Tensile Test, Compression Test, Bending Test, Shear Test, Peel Test

- Standards: ISO, ASTM, GB/T, JJG

-

- Electromechanical Universal Testing Machine, Dual Column Table-Top(5kN-50kN) The electromechanical universal testing machine is engineered for medium- to high-load material testing, offering capacities up to 50kN for tensile, compression, bending, shear, and other complex mechanical applications. It is suitable for testing both metallic and non-metallic materials.

- Test load: 5kN-50kN

- Type of test: Tensile Test, Compression Test, Bending Test, Shear Test

- Standards: ISO, ASTM, GB/T, JJG

-

- Electromechanical Universal Testing Machine, Dual Column Floor-Standing (50kN-2000kN) The electromechanical universal testing machine is engineered for high-force material testing, delivering load capacities up to 2000kN for tensile, compression, bending, shear, peel, and other demanding mechanical applications.

- Test load: 50kN-2000kN

- Type of test: Tensile Test, Compression Test, Bending Test, Shear Test, Peel Test

- Standards: ISO, ASTM

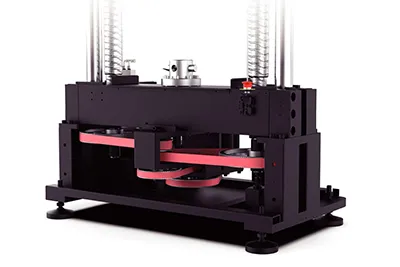

Higher Frame Stiffness

The entire load frame including the crosshead and columns is engineered for maximum stiffness. Every critical component (ball screws, nuts, bearings, sensors, etc.) is precision-matched to virtually eliminate mechanical backlash, ensuring highly stable test results.

Single-column models incorporate a high-precision linear guide rail for smooth, controlled crosshead movement, while benchtop and floor-standing models use dual guide rods passing through the crosshead to dramatically increase frame rigidity.

Faster Testing Performance

The new ETM series features a servo direct-drive architecture that replaces conventional gearbox transmission with a high-rigidity synchronous belt system. This next-generation drive design delivers significantly higher transmission efficiency, ensuring faster performance.

Enhanced Safety

An advanced collision-mitigation system continuously monitors sudden force fluctuations and automatically stops the machine to protect both the load cell and the material.

For applications requiring higher safety levels, an optional fully enclosed transparent guard with interlock functionality ensures full-coverage operator protection and compliant test operation.

Software overload limits safeguard the load cell by preventing excessive force conditions.

The mechanical limit switches add an additional layer of protection to the system.

More Intuitive Operation

An intelligent four-color status indicator (compliant with IEC 60073) provides clear visual feedback on machine status. This intuitive signaling system helps operators avoid improper actions and enhances overall operational safety and efficiency.

Simplified Test Workflow

An optional integrated touchscreen computer, combined with an intuitive software interface, streamlines test setup and execution.

Easier Maintenance

A modular controller design enables fast, plug-and-play replacement of key components, minimizing downtime. The easily removable base cover provides direct access to internal mechanisms, greatly simplifying routine inspection and maintenance.