Electromechanical Universal Testing Machine, Dual Column Table-Top

The electromechanical universal testing machine is engineered for medium- to high-load material testing, offering capacities up to 50kN for tensile, compression, bending, shear, and other complex mechanical applications. It is suitable for testing both metallic and non-metallic materials.

A high-rigidity dual-column frame paired with a wide-span crosshead delivers exceptional resistance to lateral forces, ensuring stable, high-precision performance even during large-deformation tests.

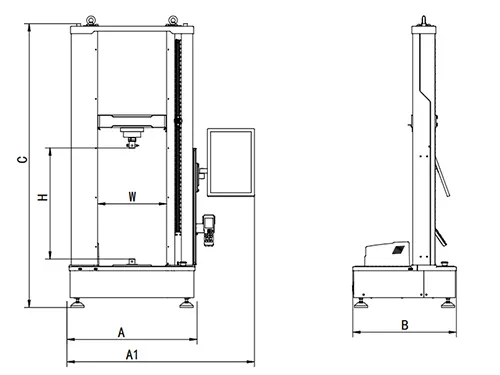

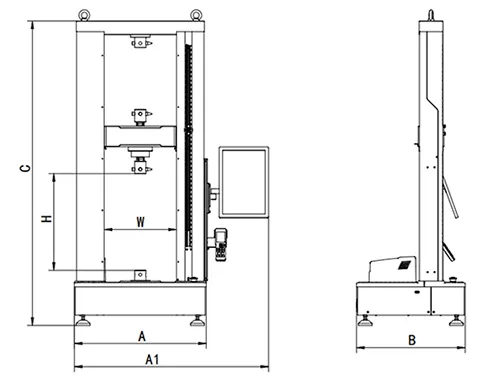

To support a broad range of specimen sizes and test configurations, the testing machine is available in both standard and extended-height frame options.

To meet advanced testing needs, the system can be equipped with a wide selection of optional accessories, including compact high-temperature furnaces, environmental chambers, automatic extensometers, and video extensometers, greatly extending its application versatility.

The dual-column guide system provides superior lateral rigidity, ensuring higher alignment accuracy and improved measurement precision. With a maximum test speed of 2000mm/min and a return speed of 2400mm/min, the system significantly boosts overall testing efficiency.

Plastics, rubber, electronic connectors, wire and cable, metal wire, films, textiles, adhesives, biomaterials, elastomers, food packaging, small components, paper products, springs, and more.

- ISO 7500-1, ISO 9513, ISO6892, ISO527, ISO 694, ISO 178, ISO 1922, ISO 7743, ISO 34, ISO 37, ISO 1184, ISO 6383, ISO 3036, ISO 13934, ISO 13937, ISO 8510, ISO 1924, ASTM E8, ASTM E4, ASTM E 83, ASTM E4, ASTM A370, ASTM D638, ASTM D695, ASTM D790, ASTM D732, ASTM D412, ASTM D882, ASTM F1306, ASTM D5053, ASTM D624

- GB/T 1040, GB/T 1041, GB/T 9341, GB/T 328, GB/T2568, GB/T 528, GB/T2790, GB/T 2791, GB/T 16491, GB/T 2611

- JJG 139, JJG 475

| Model | ||||||

| Capacity, kN | 50 | 30 | 25 | 20 | 10 | 5 |

| Frame type | Table-top | |||||

| Test space | Single / Dual space | |||||

| Max. speed, mm/min | 900 | |||||

| Min. speed, mm/min | 0.00005 | |||||

| Max. return speed, mm/min | 1500 | |||||

| Position resolution, μm | 0.01 | |||||

| Crosshead travel (H), mm | 1000 | |||||

| Test width (W), mm | 420 | |||||

| Dimension (AxBxC), mm | 770x640x1700 | |||||

| Touch screen width (A1), mm | 1350 | |||||

| Frame stiffness, kN/mm | 180 | |||||

| Net weight, kg | 370 (single space), 420 (dual space) | |||||

| Power | 1.5 kW | |||||

| Electric supply | 220V±10%, 50Hz/60Hz, single-phase | |||||

| Force range | 500N-50kN 0.2%-100%FS, 10N-250N 0.4%-100%FS | |||||

| Force accuracy | ±0.5% of reading | |||||

| Accuracy of test speed | ±0.2% of set speed | |||||

| Position accuracy | ±0.2% of set position, or 0.01mm, whichever is bigger | |||||

| Force resolution | 1/600,000FS | |||||

| Extension resolution | 1/600,000FS | |||||

| Single-channel data sampling frequency, Hz | 1200 | |||||

| Control frequency, Hz | 1200 | |||||

| Model | Overall dimension | Crosshead travel | Test width | Main unit dimensions |

| AxBxC | H | W | A1 | |

| Standard model (single space) | 770x640x1700 | 1000 | 420 | 1350 |

| Standard model (dual space) | 770x640x1760 | 900 | ||

| 300 mm extended-height model (single space) | 770x640x2000 | 1300 | ||

| 300 mm extended-height model (dual space) | 770x640x2060 | 1200 | ||

| 600 mm extended-height model (single space) | 770x640x2300 | 1600 | ||

| 600 mm extended-height model (dual space) | 770x640x2360 | 1500 |

We also provide a variety of accessories for all types of mechanical testing equipment.