Electromechanical Universal Testing Machine, Dual Column Floor-Standing

The electromechanical universal testing machine is engineered for high-force material testing, delivering load capacities up to 2000kN for tensile, compression, bending, shear, peel, and other demanding mechanical applications. Suitable for both metallic and non-metallic materials, the system is designed to meet the rigorous testing requirements of aerospace, automotive, construction steel, and other high-performance industries.

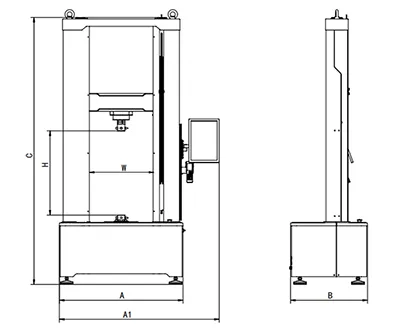

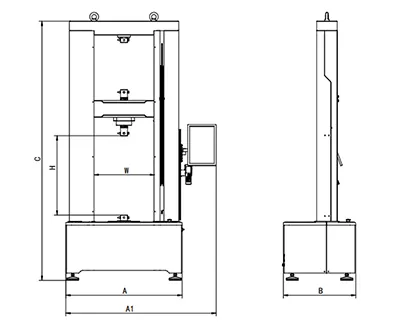

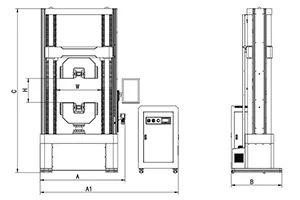

A heavy-duty portal-frame structure combined with a reinforced floor-mounted base ensures exceptional stiffness, low vibration, and highly stable loading performance under extreme force levels. To support diverse application needs, the universal testing machine offers both standard and extended-height load frame configurations.

A comprehensive range of optional accessories, such as high-temperature furnaces, environmental chambers, automatic extensometers, video extensometers, and strain measurement systems, further extends testing capability for advanced research and specialized workflows.

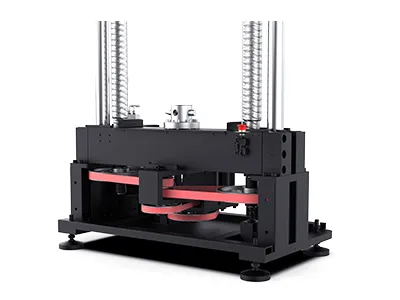

The dual-column guide system provides superior lateral rigidity, ensuring higher alignment accuracy and improved measurement precision. With a maximum test speed of 850mm/min and a return speed of 1200mm/min, the system significantly boosts overall testing efficiency.

Steel plates and bars, rebar, fasteners, anchor chains, steel strands, and other high-strength metallic materials.

- ISO 7500-1, ISO 9513, ISO6892, ISO 15630, ISO 15835

- ASTM E8, ASTM E4, ASTM E 83, ASTM A370, AC133, ASTM A416

| Model | |||||

| Capacity, kN | 50/100 | 200/300 | 500/600 | 1000 | 2000 |

| Max. speed, mm/min | 850 | 600 | 330 | 300 | 326 |

| Min. speed, mm/min | 0.00005 | 0.00005 | 0.0005 | 0.0005 | 0.0005 |

| Max. return speed, mm/min | 1200 | 1200 | 500 | 400 | 400 |

| Position resolution, μm | 0.0095 | 0.0067 | 0.011 | 0.011 | 0.011 |

| Frame stiffness, kN/mm | 270 | 380 | 900 | 1300 | 1600 |

| Dimension, mm | 1175x710x2550 | 1430x850x2760 | 1430x850x2760 | 1436x1000x3100 | 1842x1150x3803 |

| Net weight, kg | 1000 | 1225 | 2960 | 5480 | 12554 |

| Power, W | 2 | 2 | 7 | 11 | 23.5 |

| Electric supply | 380V±10%, 50Hz/60Hz, three-phase | ||||

| Force range | 500N-2000kN 0.2%-100%FS, 10N-250N 0.4%-100%FS | ||||

| Force accuracy | ±0.5% of reading | ||||

| Standards | GB/T 16825.1, ISO 7500, class 0.5, ASTM E4 | ||||

| Accuracy of test speed | ±0.2% of set speed | ||||

| Position accuracy | ±0.2% of set position, or 0.01mm, whichever is bigger | ||||

| Force resolution | 1/600,000FS | ||||

| Extension resolution | 1/600,000FS | ||||

| Single-channel data sampling frequency,Hz | 1200 | ||||

| Control frequency, Hz | 1200 | ||||

| Model | Dimension, mm | Crosshead travel, mm | Test width, mm | Touch screen width, mm |

| AxBxC | H | W | A1 | |

| Standard (single space) | 1175x710x2550 | 1350 | 600 | 1655 |

| Standard (dual space) | 1175x710x2620 | 1250 | ||

| +300mm extended-height model (single space) | 1175x710x2850 | 1650 | ||

| +300mm extended-height model (dual space) | 1175x710x2920 | 1550 | ||

| 600mm extended-height model (single space) | 1175x710x3150 | 1950 | ||

| 600mm extended-height model (dual space) | 1175x710x3220 | 1850 |

| Model | Dimension, mm | Grip distance, mm | Crosshead travel, mm | Test width,mm | Touch screen width,mm |

| AxBxC | H | W | A1 | ||

| Standard (single space) | 1430x850x2760 | 750 | 1640 | 750 | 2300 |

| Standard (dual space) | 1430x850x2840 | 650 | 1540 | ||

| +300mm extended-height model (single space) | 1430x850x3060 | 1050 | 1940 | ||

| +300mm extended-height model (dual space) | 1430x850x3140 | 950 | 1850 |

| Model | Dimension, mm | Grip distance, mm | Crosshead travel, mm | Test width, mm | Touch screen width, mm |

| AxBxC | H | W | A1 | ||

| Standard (single space) | 1570x1000x3100 | 500 | 1800 | 890 | 2450 |

| Standard (dual space) | 1570x1000x3250 | 900 | 1700 | ||

| +300mm extended-height model (single space) | 1570x1000x3400 | 800 | 2100 | ||

| +300mm extended-height model (dual space) | 1570x1000x3550 | 600 | 2000 |

| Model | Dimension, mm | Grip distance, mm | Crosshead travel, mm | Test width, mm |

| AxBxC | H | W | ||

| Standard (single space) | 1842x1150x3803 | 800 | 2300 | 1150 |

High-Temperature Furnace

High-Temperature Furnace Controller

Controller Handheld Controller (Remote Controller)

Handheld Controller (Remote Controller)

Environmental Chamber (High/Low Temperature)

Environmental Chamber (High/Low Temperature) Belt System

Belt System Alignment Grip (Coaxiality Adjustment Device)

Alignment Grip (Coaxiality Adjustment Device) Hydraulic Grip

Hydraulic Grip

We also provide a variety of accessories for all types of mechanical testing equipment.