-

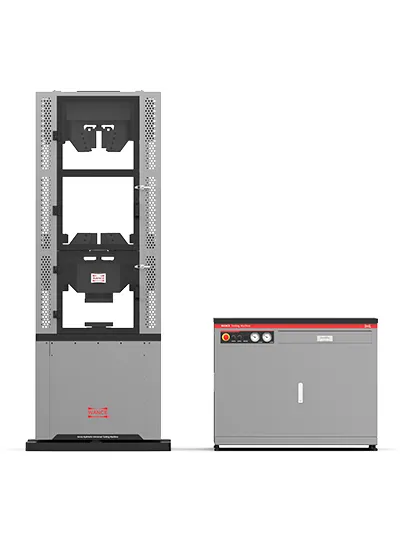

- Servo-Hydraulic Universal Testing Machine, Dual Space, Wedge Action Grip

Upper test space for tensile tests, lower test space for compression tests

Equipped with hydraulic wedge grips- Test load: 300kN~3000kN

- Type of test: Tensile Test, Compression Test, Bend & Flexural Test, Shear Test

- Standards: ISO, BS, ASTM

-

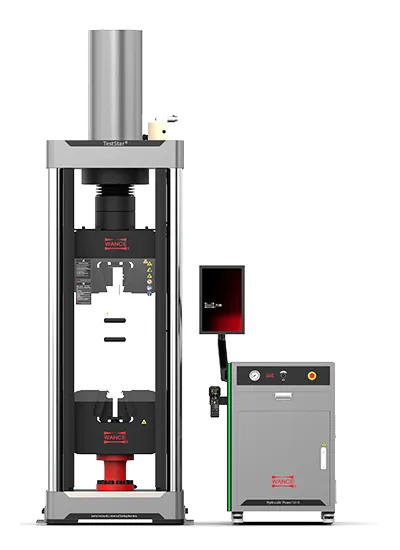

- Servo-Hydraulic Universal Testing Machine, Single Space, Wedge Action Grip

Lower space for tensile and compression testing

Equipped with hydraulic wedge grips- Test load: 600kN~2000kN

- Type of test: Tensile Test, Compression Test

- Standards: ISO, BS, ASTM

-

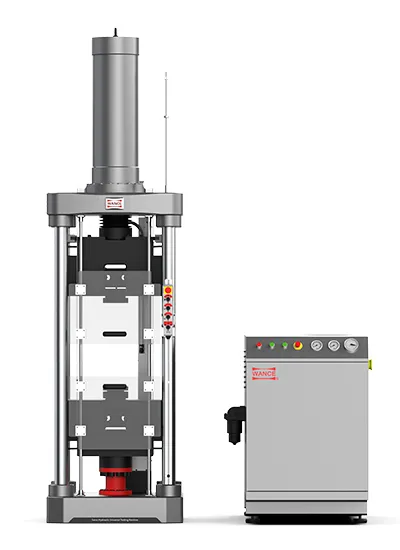

- Servo-Hydraulic Universal Testing Machine, Single Space, Side Action Grip

Lower space for tensile and compression testing

Equipped with hydraulic side-action grips- Test load: 500kN-2000kN

- Type of test: Tensile Test, Compression Test

- Standards: ISO, BS, ASTM