Request a Quote

HUT-A Series (900kN-3000kN)

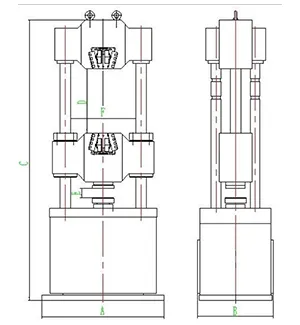

Servo-Hydraulic Universal Testing Machine, Dual Space, Wedge Action Grip

The servo-hydraulic testing machine with dual-test-space features a lower-mounted actuator and two fully independent test spaces:

- Upper test space (between the upper and lower crossheads): primarily used for tensile testing.

- Lower test space (between the lower crosshead and the test table): designed for compression, bending, shear, and flexural tests.

Both spaces can be configured by raising or lowering the lower crosshead through a lead-screw system, enabling flexible adjustment to accommodate different specimen sizes and test setups. This testing machine is widely used for tensile, compression, bending, shear, and flexural testing of metallic materials. With appropriate grips, it can also support a broad range of tests on various structural components.

Applications

Fasteners, rebar, chain, welds, castings

Standards

- ISO 7500-1, ISO 9513, ISO6892, ISO 15630, ISO 15835, BS 4449, ASTM E8, ASTM E 83, ASTM E4, ASTM A370, ASTM A416

Features

- High-Rigidity Load Frame

Heavy-duty dual-column structure with outstanding axial and lateral stiffness

High and stable alignment accuracy ensures reliable measurement - High-Resolution Draw-Wire Displacement Sensor

Excellent displacement resolution for precise movement detection, providing stable and accurate measurement - Durable Protective Enclosures

High-strength PC safety shield that saves installation space

Easy-to-operate design offering enhanced operator protection - Clean and Organized Test Area

Rubber dust covers on the test table minimize contamination

Dust curtains on lower wedge grips help maintain a tidy, low-maintenance work environment - Low-Friction Hydraulic Actuator

Corrosion-resistant and wear-resistant cylinder construction

Superior damping characteristics with a long stroke range for smooth, controlled loading - High-Accuracy Load Cell

Excellent resistance to lateral forces and strong overload capability - High-Efficiency Hydraulic Power Unit

Compact integrated design

Differential-pressure following control reduces heat generation and lowers energy consumption - Comprehensive Protection System

Mechanical limit protection

Overload protection and motor overheat protection

Emergency stop function for safe and immediate shutdown

Customization

The vertical test space can be customized according to specific test requirements.

Specifications

| Model | |||||

| Capacity, kN | 300 | 600 | 1000 | 2000 | 3000 |

| Calibration accuracy | Class 0.5 | ||||

| Force accuracy | >±0.5% | ||||

| Force range | 1%-100%FS | ||||

| Force resolution | 1/500,000FS | ||||

| Extension range | 1%-100%FS | ||||

| Extension accuracy | >±0.5% | ||||

| Extension resolution | 1/500,000 of max. extension | ||||

| Position resolution, mm | 0.004 | ||||

| Position accuracy | >±0.5% of reading | ||||

| Actuator (piston) stroke, mm | 150 | 250 | 250 | 250 | 300 |

| Actuator (piston) speed, mm/min | 0-180 | 0-140 | 0-90 | 0-70 | 0-100 |

| Middle crosshead speed, mm/min Only for test space adjustment | 350 | 270 | 310 | 360 | 240 |

| Force loading speed, FS/s | 0.05%-2% | ||||

| Column | 4 | 6 | 6 | 6 | 6 |

| Diameter of round specimens, mm | ⌀10-⌀20 ⌀20-⌀32 | ⌀10-⌀21 ⌀21-⌀31 ⌀31-⌀40 | ⌀12-⌀23 ⌀23-⌀35 ⌀35-⌀45 ⌀45-⌀55 | ⌀15-⌀30 ⌀30-⌀55 ⌀55-⌀70 | ⌀30-⌀70 ⌀70-⌀110 |

| Thickness of flat specimens, mm | 2-13 13-25 | 2-16 16-30 | 2-20 20-40 | 10-40 40-70 | 10-60 60-100 |

| Compression platens, mm | ⌀120 | ⌀150 | 200x200 | ⌀240 | ⌀280 |

| Hydraulic power unit dimension (Length x Width x Height), mm | 1150x600x900 | 1150x630x1000 | |||

| Hydraulic power unit weight, kg | 300 | 400 | |||

| HPU flow rate, L/min | 5 | 5 | 5 | 7.2 | 12 |

| Power, kW | 2.5 | 3.5 | 4 | 6 | 6 |

| Electric supply | 380V, 50Hz, three-phase, 5-line | ||||

| Frame weight, kg | 1500 | 2500 | 3500 | 6800 | 10220 |

Dimensions (mm)

| Model | Overall dimension AxBxC,mm | Max. tensile space D,mm | Max. compression space E,mm | Test width F,mm |

| HUT305A | 820x570x1955 | 520 | 520 | 410 |

| HUT605A | 940x650x2400 | 710 | 700 | 435 |

| HUT106A | 1020x670x2600 | 750 | 660 | 450 |

| HUT206A | 1370x820x3150 | 900 | 750 | 730 |

| HUT306A | 1320x950x3958 | 1200 | 1000 | 530 |

Details

We also provide a variety of accessories for all types of mechanical testing equipment.