Request a Quote

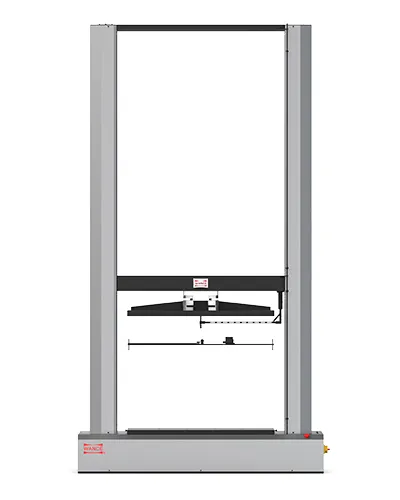

ETM Series (50kN-100kN)

Plastic Pipe Ring Stiffness Testing Machine

The ring stiffness testing machine is designed for determining the ring stiffness of large-diameter plastic pipes with a maximum test force of 50kN or 100kN. In addition to ring stiffness testing, the testing machine can also perform tensile, compression, and bending tests on various metal and non-metal materials.

Applications

- PVC Pipes: PVC-U (unplasticized rigid PVC), PVC-M (modified PVC)

- Polyolefin Pipes: HDPE pipes, PP pipes (PP-H, PP-B, PP-R)

- Corrugated Pipes: HDPE double-wall corrugated pipes, PP double-wall corrugated pipes (the most common application for ring stiffness testing)

- FRP/Composite Pipes: Glass fiber reinforced plastic pipes (GRP/FRP)

Standards

GB/T 9647-2015, GB/T 18477-2001, GB/T 16491-2007, ISO 9969:2007, ISO 13968-2008, ASTM D2412-21

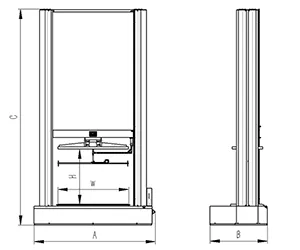

Specifications

| Model | | |

| Capacity, kN | 50 | 100 |

| Standards | ISO 7500, Class 0.5 | |

| Force range | 0.4%-100%FS | |

| Force accuracy | ±0.5% | |

| Force resolution | 1/500,000FS | |

| Position accuracy | ±0.50% | |

| Crosshead travel | 250-2000 | |

| Position resolution, μm | 0.02 | |

| Crosshead speed, mm/min | 0.005-500 | |

| Crosshead speed accuracy | within ±0.5% of set speed | |

| Max. compression space, mm | 2500 | |

| Test width, mm | 1050 | |

| Inner diameter measurement range, mm | 250-2000 | |

| Inner diameter measurement accuracy, mm | 0.01 | |

| Outside diameter measurement range, mm | 300-2500 | |

| Dimension, mm | 1690x850x3230 | |

| Electric supply | 1.3kW (220V, 50Hz, single-phase) | |

| Weight, kg | 1500 | |

We also provide a variety of accessories for all types of mechanical testing equipment.