Request a Quote

ETM Series (10MPa-20MPa)

Hydrostatic Burst Testing Machine (Hydrostatic Pressure Tester)

The hydrostatic burst testing machine is designed for long-term hydrostatic pressure testing and instantaneous burst pressure testing of plastic pipes.

The burst testing machine adopts a dual-level control architecture consisting of a computer and a programmable controller (PLC). The upper computer performs data processing, graphics generation, data management, and test sequencing, while the PLC precisely regulates pressure according to the programmed ramp rate to reach and maintain the target hydrostatic pressure.

Applications

- PVC Pipes: PVC-U (unplasticized rigid PVC), PVC-M (modified PVC)

- Polyolefin Pipes: HDPE pipes, PP pipes (PP-H, PP-B, PP-R)

Standards

ISO1167, EN921, ASTM F1335, ASTM D1598, GB/T 6111-2018, GB/T 15560 -1995, GB/T 2611-2007, GB/T 18997.1, GB/T 18997.2

Specifications

| Model | | | |

| Type | Type A | ||

| Max pressure | 10MPa | 16MPa | 20MPa |

| Test stations | 1-20 | ||

| Constant pressure display accuracy | 0.01MPa (touch screen); 0.001MPa (software) | ||

| Constant pressure accuracy | -1%-+2% | ||

| Constant pressure range | 5%-100%(10MPa, 16MPa),10%-100%(20MPa, 30MPa) | ||

| Timing range | 0-10000h | ||

| Timing accuracy | ≤±0.1% | ||

| Power requirements | AC 380V, 50Hz, 3-phase 1.5kW (1-6 stations); 5kW (7-20 stations) | ||

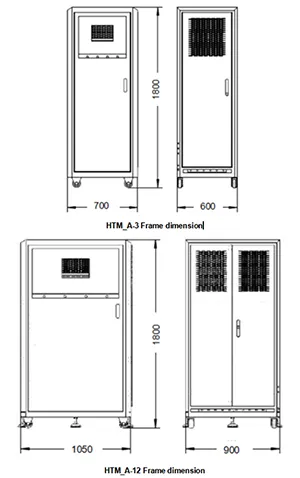

| Control cabinet dimension (AxBxC) | 700x600x1800mm (1-6 stations) 1050x900x1840mm (7-20 stations) | ||

| Control cabinet weight | 150kg (1-6 stations); 200kg (7-20 stations) | ||

We also provide a variety of accessories for all types of mechanical testing equipment.