Request a Quote

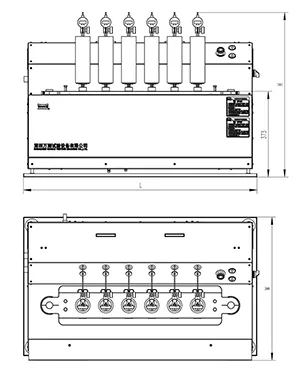

TSV Series

HDT/Vicat Testing Machine (Heat Deflection & Vicat Softening Temperature Tester)

The HDT/Vicat testing machines are widely used for determining the heat deflection temperature (HDT) and Vicat softening temperature (VST) of thermoplastic and polymer materials.

Test Materials

Plastics, rubber, and other polymer-based materials

Standards

- ISO2507, ISO75, ISO306, ASTM D1525-00, ASTM D 648-01

- GB/T8802-2001, GB/T1633-2000, GB/T1634.1-2019, GB/T1634.2-2019

Specifications

| Model | | | | |

| Test station | 3 | 4 | 6 | |

| Immersion bath volume | 9L | 9L | 14L | |

| Heat transfer medium | Dimethyl silicone oil, <300℃ Viscosity: 300 cSt, or 300 mm2/s Silicon oil: DON CORNING PMX-200 350 cSt, Shin-Etsu KF96-300 | |||

| Or transformer oil, 10#, <200℃ | ||||

| Temperature sensor | 3 | 4 | 6 | |

| Temperature range | Ambient - 300℃ | |||

| Temperature accuracy | ±0.5℃ | |||

| Heating speed | Speed A | 5±0.5℃/6min | ||

| Speed B | 12±1℃/6min | |||

| Micrometer | 3 | 4 | 6 | |

| Deformation measurement range | 0-10mm | |||

| Deformation resolution | 0.001mm | |||

| Deformation measurement accuracy | 0.003mm | |||

| Vicat Loading capacity: | GA=10N±0.2N, GB=50N±1N | |||

| HDT test | Method A: Fibre Stress 1.80Mpa | |||

| Method B: Fibre Stress 0.45Mpa | ||||

| Method C: Fibre Stress 8.00Mpa | ||||

| HDT test span | Outer span: 100mm, ASTM D648 Inner span: 64mm, ISO 75 | |||

| Maximum heating power | 4.5kW | |||

| Electric supply | AC380V±10% 50HZ 16A, 3-phase | |||

| Dimension (LxWxH) | 816x620x720mm | 1020x620x720mm | ||

| Weight | 115kg | 180kg | ||

| Cooling | 45min (280℃ to 25℃, with chiller) | |||

We also provide a variety of accessories for all types of mechanical testing equipment.