DIT302

Drop Weight Impact Testing Machine for Plastic Pipes

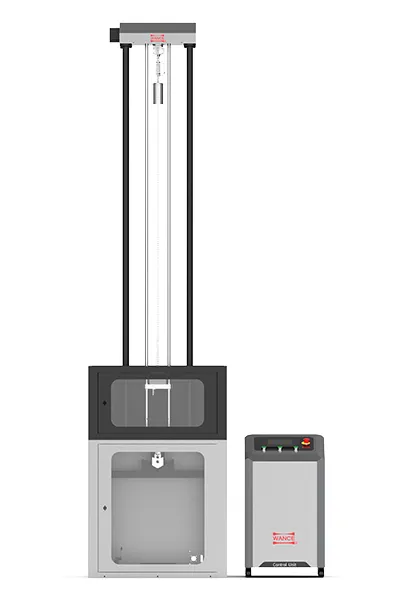

The drop weight impact tester is engineered for assessing the impact resistance of non-metallic pipes and plates. Impact performance is evaluated by dropping a defined weight from a specific height onto a designated point on the material, with the resulting damage or failure mode used to determine the material’s toughness and deformation resistance.

Applications

- Plastic Sheets/Plates: Polycarbonate (PC) sheets, Polypropylene (PP) sheets, PVC sheets, Acrylic (PMMA) sheets, tc.

- Plastic Pipes/Fittings: PVC water supply pipes, PE gas pipes, PPR hot and cold water pipes, etc.

Standards

ISO 3127, ISO 4422, BS EN 12608, BS EN 744, ASTM D2444, GB/T 14152-2001, GB/T 10002.1-2006, GB/T 8814, GB/T 6112, GB/T 14153, GB/T 11548

Request a Quote

Specifications

| Model | DIT302 | |||

| Type | A-1 | A-2 | A-3 | A-4 |

| Maximum impact energy, J | 300 | |||

| Maximum impact height H, mm | 2000 | |||

| Maximum pipe diameter, mm | ⌀400 | ⌀630 | ⌀1200 | ⌀1600 |

| Striker lifting speed, m/min | 8 | |||

| Height measurement accuracy, mm | ≤±10 | |||

| Distance between striking point and specimen center, mm | ≤±2.5 | |||

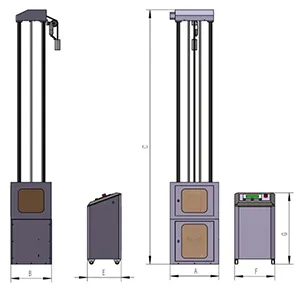

| Dimension AxBxC (LxWxH, mm) | 600x 500x3200 | 880x520x3500 | 1700x1100x4400 | 2200x1100x5220 |

| Electric supply | 300W (220V±10%, 50Hz, single-phase) | 1.2kW (380V±10%, 50Hz, 3-phase) | ||

| Weight, kg | 500 | 600 | 1000 | 1200 |

We also provide a variety of accessories for all types of mechanical testing equipment.