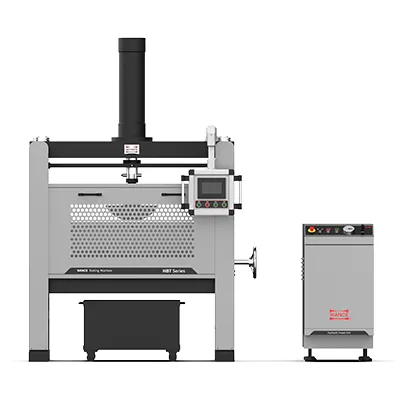

HBT305D (300kN)

Rebar Bend & Re-bend Testing Machine

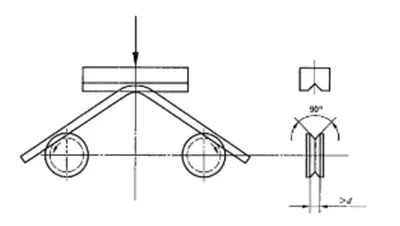

The vertical rebar bending testing machine is designed for bend and rebend evaluation of metallic materials including bars, tubes, plates, polygonal-section materials, and construction-grade ribbed rebar. It supports 180° bending, re-bending, and 90° pipe bending, delivering a maximum forming force of 300kN.

Standards

GB/T 232, GB/T 244, GB/T 3091, GB/T 8162, GB/T 13793, GB/T 28897, ISO 7438, ISO 8491, ISO 559, ISO 6935, BS 4449, BS 4482, BS EN 10080, DIN488-2, SS 212540, ASTM A775, ASTM A706

Request a Quote

Specifications

| Max pushing force, kN | 300 |

| Vertical cylinder max travel, mm | 500 |

| Vertical cylinder speed without specimen, mm/s | 0.5-4 |

| Support roller diameter, mm | 45 |

| Distance between supports, mm | 10-630 |

| Mandrel diameter, mm | According to test standards |

| Diameter of round specimens, mm | Ф6-Ф50 |

| Flat specimen thicknessxwidth, mm | (6-40)x50 |

| Max. bending angle, ° | 180 |

| Electric supply | 380V, 50Hz, 3-phase |

| Power consumption, kW | 5.5 |

| Main dimension, mm | 1470x735x2390 |

| Weight, kg | 1700 |

| Hydraulic power unit dimension, mm | 500x880x990 |

| Hydraulic power unit weight, kg | 250 |

| Hydraulic oil | 46# anti-wearing hydraulic oil, 90 liter |

Test procedure

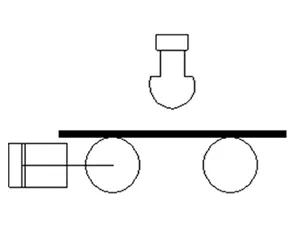

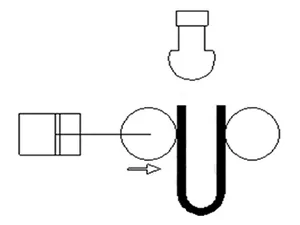

180° Rebar Bend Test

Step 1: Place the specimen

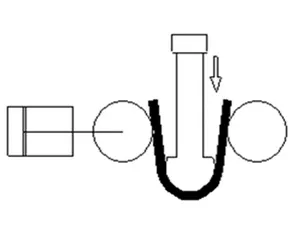

Step 1: Place the specimen Step 2: Start bending

Step 2: Start bending Step 3: Return the mandrel

Step 3: Return the mandrel  Step 4: Bend to 180°

Step 4: Bend to 180°

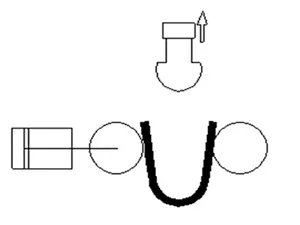

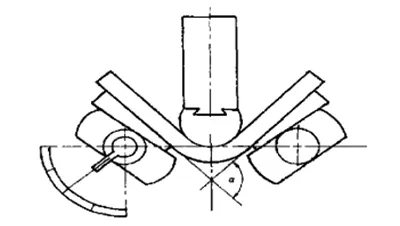

Step 1: Bend to 90°

Step 1: Bend to 90°  Step 2: Re-bend to 20°

Step 2: Re-bend to 20°

We also provide a variety of accessories for all types of mechanical testing equipment.