Request a Quote

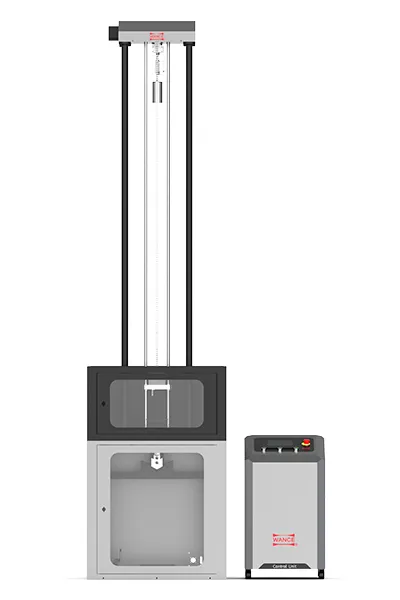

DIT-A Series (300J)

Drop Weight Impact Testing Machine for Plastics

The drop weight impact tester is engineered for assessing the impact resistance of non-metallic pipes and plates. Impact performance is evaluated by dropping a defined weight from a specific height onto a designated point on the material, with the resulting damage or failure mode used to determine the material’s toughness and deformation resistance.

Standards

ISO 3127, ISO 4422, BS EN 12608, BS EN 744, BS 2782-11: method 1108C, ASTM D2444, GB/T 14152, GB/T 10002.1, GB/T 8814, GB/T 6112, GB/T 14153, GB/T 11548

Features

- Automatic anti-rebound systems

- Automatic impact zero-point positioning

- Automatic hammer lift to preset height

- Adjustable test space with movable crossbeam

- PLC-controlled weight positioning: Delivers stable, consistent drop motion with precise height control and continuous system monitoring for improved operational safety.

- Low-friction guide rod system: Ensures smooth vertical travel of the weight and accurate positioning at the intended impact point.

- Full safety enclosure: Prevents debris ejection during high-energy drops and provides comprehensive protection for operators throughout the test cycle.

Specifications

| Model | DIT302 | |||

| Type | A-1 | A-2 | A-3 | A-4 |

| Max. impact energy, J | 300 | |||

| Max. impact height H, mm | 2000 | |||

| Max. pipe diameter, mm | ⌀400 | ⌀630 | ⌀1200 | ⌀1600 |

| Striker lifting speed, m/min | 8 | |||

| Height measurement accuracy, mm | ≤±10 | |||

| Distance between striking point and specimen center, mm | ≤±2.5 | |||

| Dimension A x B x C (LxWxH, mm) | 600x 500x3200 | 880x520x3500 | 1700x1100x4400 | 2200x1100x5220 |

| Control cabinet dimension (LxWxH, mm) | 420x500x890 | |||

| Electric supply | 300W (220V±10%, 50Hz, single-phase) | 1.2kW (380V±10%, 50Hz, 3-phase) | ||

| Weight, kg | 500 | 600 | 1000 | 1200 |

We also provide a variety of accessories for all types of mechanical testing equipment.