Request a Quote

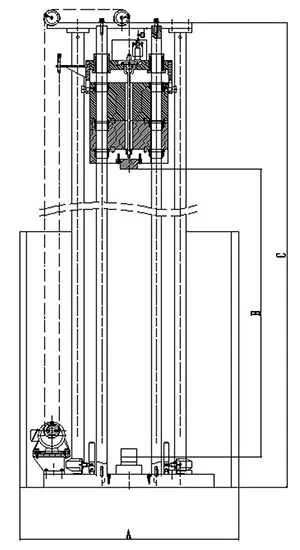

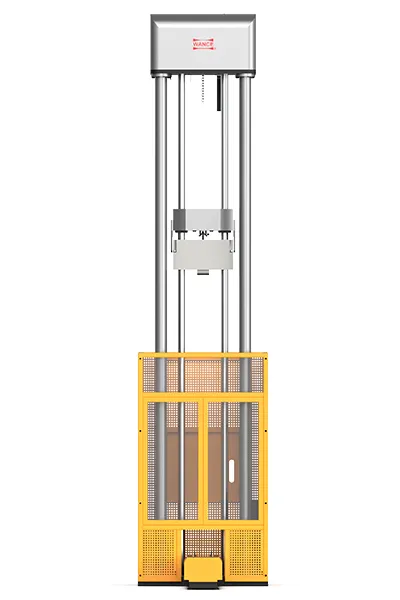

DIT-B Series (2000J-6000J)

Drop Weight Impact Testing Machine for Metals, Nil-Ductility Transition (NDT) Temperature

This drop weight impact testing machine is specially designed to determine the Nil-Ductility Transition Temperature (NDT) of ferritic steels, including plates, sections, cast steel, and forged steel.

Standards

ASTM E208, GB/T 6803

Features

- High-reliability PLC control system and a touch screen interface, ensuring stable, accurate, and user-friendly operation.

- Automatic specimen feeding & positioning

- Heavy-duty frame for superior stability: Built with thick steel plate structural frame, the testing machine maintains excellent rigidity under high-energy impacts

- High-strength drop weight assembly: Drop weight made from high-strength alloy steel, ensuring excellent impact resistance and durability

- Precision height control with chain-driven lifting system

- Self-locking weight holding mechanism

- Full-enclosure safety guard

- Dedicated support tooling for easy anvil replacement

Specifications

| Model | | | |

| Max. energy, J | 2000 | 3000 | 6000 |

| Minimum energy, J | 300 | 350 | 350 |

| Max. tup mass, kg | 70 (40+30) | 100 (45+55) | 200 (100+100) |

| Tup mass accuracy | ±1% | ||

| Drop height, mm | 750-3062 | ||

| Velocity of drop, m/s | 3.8-7.8 | ||

| Speed of tup raise, m/min | 7 | ||

| Height accuracy, mm | ≤±10 | ||

| Hardness of tup nose | HRC58-62 | ||

| Radius of tup nose, mm | R25±0.1 | ||

| Hardness of support anvil | HRC58-62 | ||

| Alignment accuracy of center of tup nose, specimen and anvil center, mm | ≤±2.5 | ||

| Support anvil span, mm | P-1: 305 P-2, P-3: 100 | ||

| Specimen dimension, mm (length x width x thickness) | P-1: (360±1)x(90±2)x(25±2.5) P-2: (130±1)x(50±1)x(20±1) P-3: (130±1)x(50±1)x(16±0.5) | ||

| Weight, kg | 1500 | ||

| Electric supply | 380V 10A 50Hz, 3-phase, 5-line | ||

| Air supply | 0.4-0.7MPa, ⌀6 quick coupler for air pipe | ||

We also provide a variety of accessories for all types of mechanical testing equipment.