Drop Weight Impact Testing Machine for Composites

The drop weight impact tester is specifically designed for low-velocity impact damage evaluation of composite laminate materials. It supports standardized impact-energy assessment for aerospace and automotive, fully complying with international test methods.

ASTM D 7136/D 7136M, GB/T21239

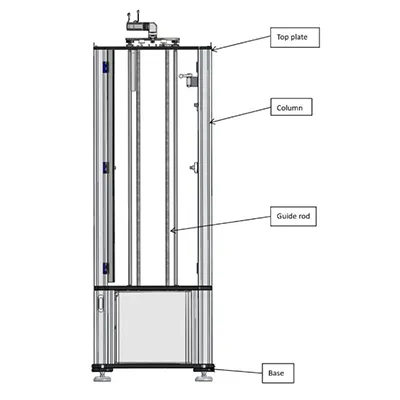

High-stability frame with precision guide system

The guide rails are precision-ground shafts with a chrome-plated, hardened surface, providing excellent straightness and high dimensional accuracy. Both ends of each shaft are threaded and tension-mounted, ensuring high rigidity of the frame and guide structure while preventing loosening of structural connections caused by vibration during repeated impact testing.

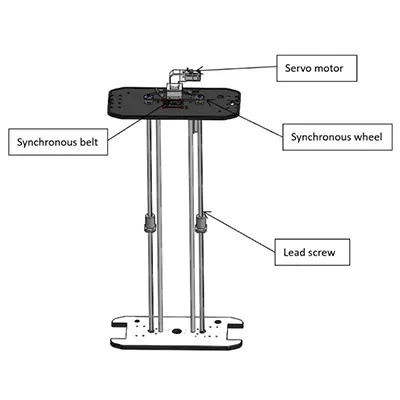

Servo-motor lifting system with self-locking safety

A high-efficiency servo motor delivers low noise, stable lifting performance, and precise vertical positioning. An integrated automatic brake provides immediate self-locking in the event of power loss, preventing accidental weight drop.

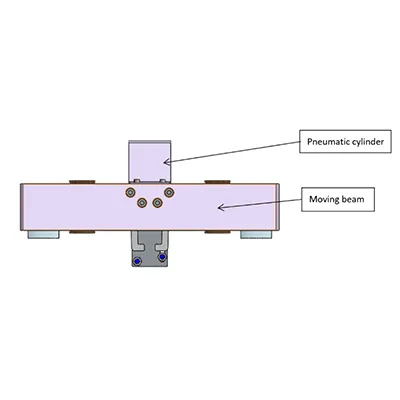

Secure weight-release with dual safety monitoring

The release mechanism features an automatic self-locking structure: once lifted, the weight is securely latched and cannot disengage under its own weight. A proximity-switch monitoring function verifies proper engagement. If locking is incomplete, the crossbeam will not rise. Pneumatic actuation ensures consistent release performance and long service life.

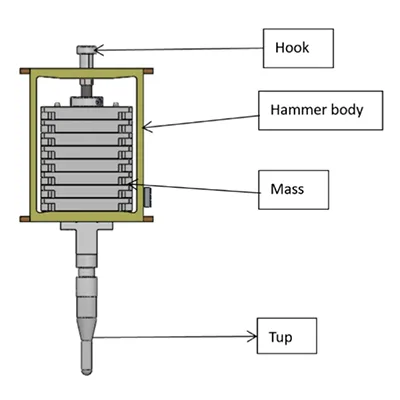

Weight assembly for flexible energy configuration

The weight assembly includes the main body, hook, guide block, weight, masses, and reflective plate. Default mass is 5.5 kg and can be increased to 29.5 kg through modular weight addition. The weight is spherical (D 16±0.1mm) and manufactured from hardened alloy steel, which fully complies with ASTM D7136.

Anti-rebound device to eliminate secondary impact

After the initial strike, any upward rebound is immediately captured by the anti-rebound mechanism, preventing unintended secondary impacts and ensuring test validity and repeatability.

Standard pneumatic clamping fixture with full protective enclosure

The clamping fixture follows ASTM D7136 requirements, providing a 125x75mm opening for composite laminate specimens. Specimens (150x100mm) rest on the support plate and are pneumatically clamped prior to impact. A fully enclosed safety guard surrounds the fixture; the pneumatic clamp operates only when the door is securely closed, ensuring operator safety.

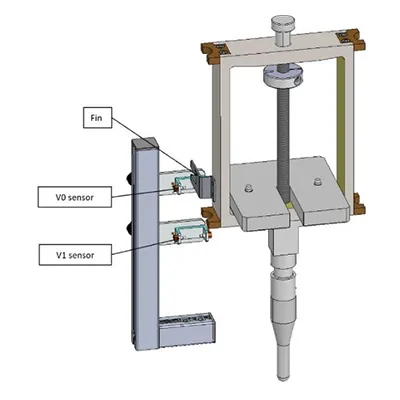

High-precision velocity measurement system

A laser displacement sensor (82mm range, effective measurement distance 115-197mm) captures hammer velocity with high accuracy, enabling precise calculation of impact energy and improving overall test reliability.

| Model | DIT302E |

| Energy | 6-300 J |

| Impact speed | 1.47-4.65 m/min |

| Hammer lifting | 1m/min-3m/min, adjustable |

| Impact height | 110-1100 mm |

| Hammer positioning accuracy | 1.0 mm |

| Mass | 5.5-29.5 kg |

| Hammer sphere diameter (half-sphere) | 16mm |

| Force transducer | 100kN |

| Force transducer static linearity error | ±1%FS (10%-50%FS) ±2% of reading (50%-100%FS) |

| A/D sampling resolution | 16bits |

| Max. sampling frequency | 2MHz |

| Frequency response | 500kHz |

| Dynamic error | < 2% |

| Machine dimension (Length x Width x Height) | 1430x670x2630 mm |

| Electric supply | 400W (AC220V±10% 50Hz) |

| Weight | 550 kg |

-

Force sensor

Force sensor -

Electrical control cabinet

Electrical control cabinet -

Pneumatic specimen fixture

Pneumatic specimen fixture -

Environmental chamber

Environmental chamber

We also provide a variety of accessories for all types of mechanical testing equipment.