Pendulum Impact Testing Machine for Metals, Charpy Impact Test

The pendulum impact testing machine is engineered for evaluating the impact resistance of metallic materials under dynamic loading conditions.

ISO 148, EN10045, ASTM E23, GB/T 229, GB/T 12778, GOST 9454

Charpy impact test

Pneumatic brake for maximum safety

A high-responsiveness pneumatic brake halts the pendulum immediately during power interruptions or emergency situations, greatly enhancing operational safety during testing.

Automatic pneumatic locking

Once the pendulum reaches the upper release point, a pneumatic lock engages automatically, improving both operator safety and testing efficiency.

Safety Enclosure

The separate, fully enclosed aluminum safety shield is easy to remove for maintenance, while the glass viewing window provides clear visibility of the test process. A lower metal mesh layer prevents fractured specimen fragments from ejecting, ensuring the highest level of operator protection.

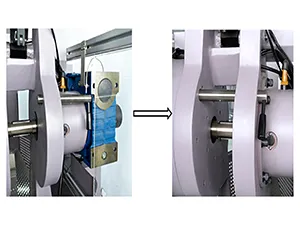

Fast Specimen Alignment

A pneumatic centering mechanism enables rapid and precise specimen positioning, which is especially valuable in low-temperature applications where reducing heat loss during specimen transfer is critical.

Maintenance safety lock

A dedicated mechanical lockout pin can secure the pendulum during maintenance procedures, ensuring maximum technician safety.

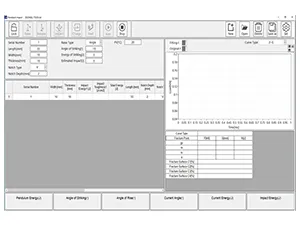

Software control operation (optional)

With the optional PC-based control package, the operator only needs to load the specimen, while all remaining functions are handled through software commands.

Fully automated operation (optional)

Combining the automated specimen-feeding system with the software suite allows the impact testing machine to operate in fully automated mode.

Low-temperature system (optional)

Conditioning down to -180°C supports Charpy testing of materials requiring low-temperature toughness evaluation.

High-temperature furnace & transfer system (optional)

A high-temperature furnace capable of reaching 900°C, along with a dedicated transfer mechanism, enables elevated-temperature impact testing.

| Model | TSP452D1 | ||

| Maximum energy | 450J | ||

| Optional pendulum | 150J, 300J | ||

| Angle of striking | 150°±1° | ||

| Angle measurement resolution | 0.025° | ||

| Distance from the axis of support to the center of percussion | 750mm | ||

| Velocity of striking | 5.24m/s | ||

| Absorbed energy under free swing | ≤0.4% | ||

| Support | Support span | 40mm | |

| Radius of curvature of supports | 1mm | ||

| Angle of taper of supports | 11°±1° | ||

| Striking tup | Radius of striking edge | 2mm | |

| Angle of striking tip | 30° | ||

| Thickness of striker | 16mm | ||

| Specimen dimension | 55x10x10mm 55x10x7.5mm 55x10x5mm | ||

| Weight | 1400kg | ||

| Dimension(A x B x C) Including protection shield | 2150x2150x860mm | ||

| Power requirements | 3-phase, 5-line, AC 380V±10% 50Hz 1 kW | ||

| Pendulum moment | 150J | 80.3848 Nm | |

| 300J | 160.7695 Nm | ||

| 450J | 241.1543 Nm | ||

-

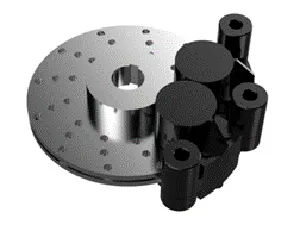

Pendulum

Pendulum -

Specimen support and anvil

Specimen support and anvil -

Motor and reducer

Motor and reducer -

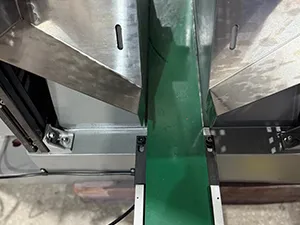

Specimen feeding conveyor

Specimen feeding conveyor -

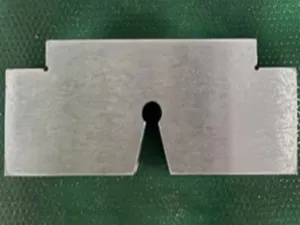

Span alignment block

Span alignment block -

Accessories for high temperature test

Accessories for high temperature test

We also provide a variety of accessories for all types of mechanical testing equipment.