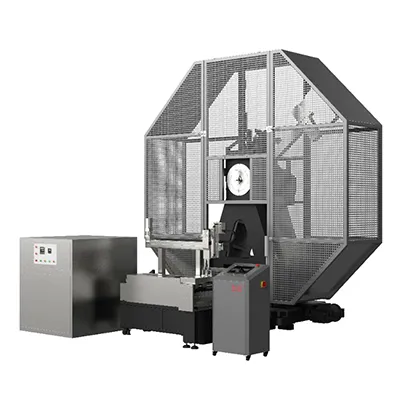

PIT-E Series (5000J-7500J)

Pendulum Impact Testing Machine for Metals, Dynamic Tear Testing (DT Test)

The pendulum impact testing machine is specifically designed for dynamic tear (DT) testing of metallic materials.

Standards

ASTM E604, GB/T 5482

Request a Quote

Features

- Fully automated operation

This impact testing machine configuration supports automatic specimen feeding, impact execution, pendulum lifting, and specimen removal, enabling a true fully automated workflow. - Heavy-duty base and frame

A high-strength carbon-steel base combined with a 300x300 H-beam steel frame delivers outstanding rigidity and structural stability. This architecture effectively absorbs impact-induced vibration. The specimen anvil is manufactured from 45# steel (forged and tempered), offering excellent strength and high measurement accuracy. - High-strength pendulum

Engineered for high axial and lateral stiffness, the pendulum ensures consistent and reliable energy transfer during each impact. The swinging pendulum assembly includes: Pendulum body, arm, hook, and striker. The pendulum arm is machined from 45# steel into an H-beam profile. The body and the arm are fully tempered for enhanced structural integrity. The striker is made from hardened tool steel, reaching a hardness of ~62 HRC, providing exceptional wear resistance. - Three impact energy levels

Multiple selectable energy levels can be achieved without changing the pendulum, offering greater convenience and improved test efficiency. - Automated specimen feeding and positioning system

A system designed for fast, precise, and safe specimen handling Workflow:

① Specimen placed on the feed table;

② Positioning cylinder sets specimen length;

③ Transfer cylinder moves the specimen to the pre-support zone;

④ Loading cylinder pushes the specimen into the final test position;

⑤ All cylinders automatically return to default positions - Robust specimen support assembly

A combined support-block and anvil structure provides high load-bearing capability. The anvil is produced from hardened Cr-Mn steel (58-62 HRC), ensuring stable support under high-energy impact conditions. - Siemens-based control platform

A Siemens S7-200 PLC provides reliable control logic, a high degree of automation, reduced operator workload, and improved productivity and operational safety.

Specifications

| Model | | |

| Maximum impact energy | 5000J | 7500J |

| Angle of striking | 135° | 135° |

| Angle resolution | 0.1° | 0.1° |

| Distance from the axis of support to the center of percussion | 1380 | 1500 |

| Velocity of striking | 6.797m/s | 7.087m/s |

| Support span, mm | 165±0.8 | 165±0.8, 406±1.5, 500±1.5, 600±1.5 (adjustable) |

| Radius of curvature of supports, mm | 12.7±0.8 | 12.7±0.8, 35±0.5 |

| Angle of taper of supports | 11°±1° | 11°±1° |

| Radius of striking edge, mm | 12.7±0.8 | 12.7±0.8, 38±0.5 |

| Angle of striking tip | 30°±1° | 30°±1° |

| Thickness of striking tip, mm | 37 | 37 |

| Specimen dimension, mm | (180±2) x (40±1) x (5~16) | Standard specimen: 180x40x5~16 Non-standard specimen: 460x120x25, 550x160x32, 650x200x40 |

| Weight | 6500kg | 10000kg |

| Dimension, mm | 3700x2350x3800 | 3800 x 2905 x 3880 |

| Power requirements | 3-phase, 5-line, AC 380V±10% 50Hz 850W | 3-phase, 5-line, AC 380V±10% 50Hz 5Kw |

We also provide a variety of accessories for all types of mechanical testing equipment.