Request a Quote

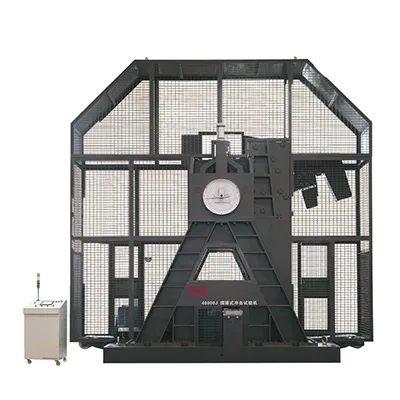

PIT-E Series (20kJ-100kJ)

Pendulum Impact Testing Machine for Metals, Drop Weight Tear Test (DWTT)

This pendulum impact testing machine is specifically engineered for drop weight tear testing (DWTT) of ferritic steels, pipeline steels, and other metallic materials. This test evaluates a material’s impact resistance by measuring DWTT impact energy under dynamic loading. It also allows observation of fracture appearance within the ductile-to-brittle transition temperature range. The equipment is widely used in the development of high-grade thick-wall pipeline steels and ferritic steels.

Standards

ASTM E436, GB/T 8363, API RP 5L3

Features

- Heavy-duty base & frame

A reinforced base and high-stiffness frame ensure long-term dimensional stability and accurate energy measurement while effectively damping residual vibration following each impact event. - Three impact energy levels

Multiple selectable energy levels can be achieved without changing the pendulum, offering greater convenience and improved test efficiency. - Fully automated operation

This impact testing machine configuration supports automatic specimen feeding, impact execution, pendulum lifting, and specimen removal, enabling a true fully automated workflow. - Precision pendulum system

A servo motor delivers constant torque for accurate, repeatable pendulum elevation. The cycloidal drive directly drives the clutch, providing a compact structure with a high reduction ratio, strong overload capacity, and minimal maintenance requirements. - Automatic specimen collection

After testing, specimens are automatically transferred outside the protective enclosure for safe and efficient retrieval, significantly increasing throughput in high-volume testing environments. - Full safety protection

A fully enclosed safety guard prevents specimen debris from escaping during impact. Integrated door-interlock and limit-switch protection ensures operation only when all safety conditions are properly satisfied. - Siemens-based control platform

A Siemens S7-200 PLC provides reliable control logic, a high degree of automation, reduced operator workload, and improved productivity and operational safety.

Specifications

| Model | | |

| Max. impact energy | 20000J, 30000J, 40000J | 100000J |

| Angle of striking | 81.6°, 106.3°, 135° | 135°-63° |

| Distance from the axis of support to the center of percussion | 2000mm | 2400mm |

| Velocity of striking | 5.788m/s, 7.088m/s, 8.183m/s | 5.07-8.96m/s |

| Support span | 254±0.8mm | |

| Radius of curvature of supports | 14.3±0.5mm | |

| Angle of taper of supports | 11° | |

| Radius of striking edge | 25.4±0.4mm | |

| Thickness of striking tip | 50.8±0.8mm | |

| Specimen dimension | 305 x 76.2 x (3-40) mm | |

| Weight | 40000kg | |

| Electric supply | AC 380V±10%, 50Hz, 3-phase, 5-line | |

We also provide a variety of accessories for all types of mechanical testing equipment.